Silver Award,Scientific and Technological Progress Award,The 10th ECF Tech Award

Project: Research and Practice on Efficient Energy Replenishment and Pressure Restoration Technology for Low

Company:Oil and Gas Technology Research Institute

Project Title: Research and Practice on Efficient Energy Replenishment and Pressure Restoration Technology for Low-Yield Horizontal Wells in Changqing Shale Oil

Participating Enterprise: Oil and Gas Technology Research Institute, PetroChina Changqing Oilfield Company

Award Received: Scientific and Technological Progress Award - Silver Award

Achievement Level: International Advanced Level

Project Number: ECF-2025-SET-1013

Main Participants: Lu Hongjun, Yan Changhao, Mu Lijun, Bai Xiaohu, Bai Jianwen, Wang Pan, Ren Yong, Kang Bo, Ren Jiawei, Bai Yuen, Zhang Yushuo, Li Zhuanhong

Expert Review Comments:

International advanced level. This project addresses the challenges of poor conventional production enhancement in low-yield shale oil horizontal wells and rapid depletion of formation energy. It innovatively proposes the “energy-replenishing re-pressurization” technical approach, establishing a synergistic production enhancement system integrating “fracture network–energy–medium.” Through key technologies such as pre-repressurization fracture diagnosis, precision energy replenishment, multi-stage temporary plugging for complex fracture stimulation, and integrated geological-engineering design, the system significantly enhances fracture complexity and mobilized reservoir volume, achieving substantial increases in recovery rates for mature wells. The technology has been applied to over 130 wells in the Changqing Oilfield, boosting oil production by more than 1.5 million tons. It delivers outstanding economic and social benefits, with a highly replicable and scalable technical model. This provides a systematic solution for profitable development in mature unconventional oil and gas fields.

Main Innovations:

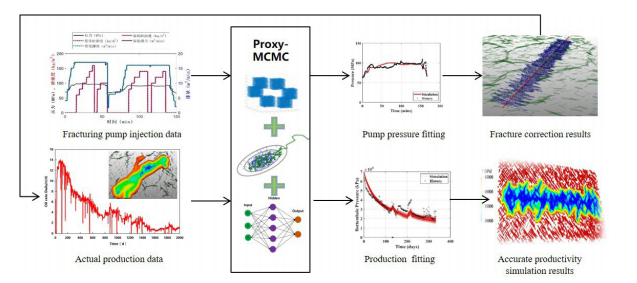

Addressing the challenge of low fluid content and low production in mature tight/shale oil fields of Changqing Oilfield after prolonged production, where conventional repeated stimulation measures prove ineffective, we innovatively propose enhanced recovery through energy-supplemented re-pressurization for horizontal tight/shale oil wells. Precise replenishment of formation energy is achieved through diagnostic evaluation of existing fractures prior to re-pressurization. Integrated geological-engineering approaches densify fracture placement to enhance sweet spot mobilization. Pre-set multistage temporary plugging followed by repeated fracturing creates complex fracture networks. Synergistic interaction among fracture networks, energy, and media activates multiple production enhancement mechanisms, ultimately achieving multifaceted recovery improvement in mature horizontal wells through enhanced flow pathways, energy replenishment, enhanced permeability, and oil displacement.

Main Uses and Technical Principles:

In mature tight/shale oil fields of Changqing Oilfield, initial horizontal well stimulation is often inadequate. Prolonged depletion-style production depletes formation energy, rendering conventional re-stimulation ineffective for stable production. To address this, the energy-replenishing re-stimulation technology for horizontal wells was developed. It aims to improve flow pathways, enhance formation energy, promote wetting and oil displacement, and comprehensively boost recovery rates in mature wells. The technology achieves this through: - Pre-repressurization diagnostic testing of existing fractures to precisely replenish energy in mature sections - Integrated geological-engineering design employing densified fracture placement to increase sweet spot utilization - Multi-stage temporary plugging and repeated fracturing using pre-set plugs to create complex fracture networks - Synergistic mechanisms including fracture network expansion, energy replenishment, and medium displacement to substantially boost recovery rates in mature horizontal wells.

Technical Applications:

The technology is undergoing continuous testing, promotion, and application in Changqing Oilfield. After implementation in test wells, daily oil production surged from an average of 0.83 tons to 13.39 tons—more than 15 times the initial production level—with average well recovery rates increasing by over 8.9%. As of September 2025, the technology has been applied to over 130 wells in Changqing Oilfield, cumulatively increasing oil production by more than 1.9 million tons. Annual well applications across various production plants in Changqing Oilfield continue to grow, generating nearly 1 billion yuan in economic value for the field. This technology has made a significant contribution to the landmark achievement of exceeding 10,000 tons of daily shale oil production at Changqing Oilfield, exploring an effective technical pathway for substantially enhancing recovery rates in mature tight/shale oil fields.

Having achieved remarkable results in Changqing Oilfield, this technology's successful experience can be extended to other mature tight shale oilfields across China, such as the Southwest Oil and Gas Field, Daqing Oilfield, and shale reservoirs in Xinjiang and Qinghai. Simultaneously, this technology holds reference value for international tight/shale oil development, particularly for fields characterized by strong reservoir heterogeneity and low recovery rates in mature wells. Through technology export and international cooperation, it can enhance China's influence in the global unconventional oil and gas development sector.