The 9th ECF Tech Award for Exploration & Production Technology

Project:Key Tech for COOP Develop of Stereoscopic Well Pattern & Fracture Network in Continental Shale Oil

Company:PetroChina Research Institute of Petroleum Exploration & Development

Project Full Name:Key Technologies for Cooperative Development of Stereoscopic Well Pattern and Fracture Network in Continental Shale Oil

Company:PetroChina Research Institute of Petroleum Exploration & Development

Awarded:Exploration & Production Technology

Standard: International Advanced Level

Project Number:ECF-2024-SEP-1011

Principal Accomplishers: Lei Zhengdong, Tao Zhen, Ji Dongqi, Peng Huanhuan, Liu Yishan, Zhang Guangming, Yan Yiqun, Tao Jiaping, Liu Yuqi

Key Innovation Points:

1. A high temperature and high pressure micro-nano flow visualization system was developed, and amovability evaluation method for the multi-scale pore structure fiusion was formed to support thedevelopment of shale oil sweep-spots.

2. A 3D geomechan ical model considering bedding fractures is established, and an integrated modelingmethod for horizontal well parameter optimization is formed, which provides scientific basis for horizontal well trajectory and parameter optimization;

3: A multi-parameter collaborative technical and economic integration optimization method forstereoscopic shale oil well pattern and fracture network coupling is established, which greatly improves thereserve utilization.

4: The integrated evaluation technology of formation and horizontal well for rational utilization offormation energy was formed, and the optimization method of multi-mechanism collaborative full-cycleproduction system was established.

Main Application and Technical Principal:

The project involves a set of technologies suitable for continental shale oil development, including: 1development of a v isual experimental method for oil occurrence and flow behaviors under high temperatureand pressure, establishment of a shale oil mobility and matrix oil flow evaluation method, and a scientifibasis for the selection of sweet-spots, 2. Establishment of a stereoscopic geological model consideringbedding fractures, forming a parameterized optimization method for integrated geoengineering horizontalwells, providing a quantitative basis for horizontal well deployment and differentiated fracturing modes; 3based on the stereoscopic staggered well pattem, the multi-parameter collaborative technical and economicintegration optimization method of' well pattern and fracture network is constructed to support the oirecovery factor increase from 8% to 12.6%; 4. an integrated node flow evaluation method of shale oilformation and horizontal well wellbore was established to form a multi-mechanism collaborative full-lifeproduction optimization method to support the 30% increase of a single well cumulative production.

Technology Application:

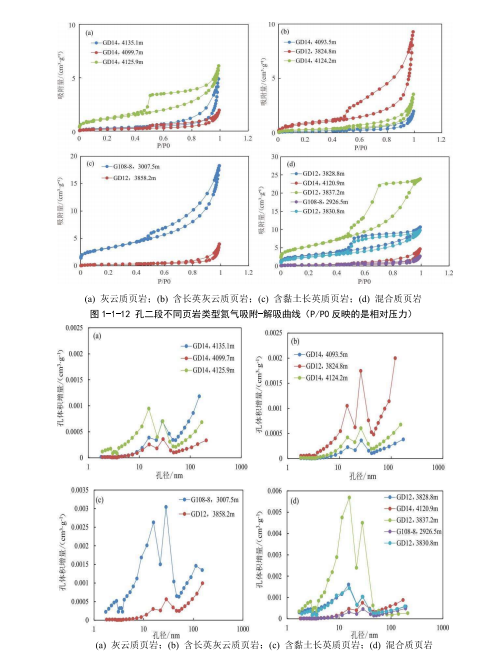

This technology applies the full-scale evaluation method of pore structure to clarify the micro pore throat structure characteristics of the reservoir, using cast thin section and scanning electron microscope to observe that the oil reservoir of Jimushar Luchaogou Formation mainly develops a residual intergranular pores, intergranular soluble pores, intragranular soluble pores, inter-pinhole pores, organic pores and microfractures, with pore diameters more than less than 1um, and that the main pore types of the second section of the Cangdong depression holes are intergranular pores, inter-pinhole pores, soluble pores, organic matter pores and microfractures The main types of pores in the second section of Cangdong Depression are intergranular pores, inter-pin pores, dissolution pores, organic matter pores and microcracks. The lower limit of movable pore throat of Luchaogou shale oil is 20nm, and the lower limit of obvious movable pore throat is 60nm, and the percentage of movable volume contributed by pore throat larger than 60nm is up to 80%: through the change of pore space of cryogenic helium adsorption before and after the oil washing, and the correlation between pore space of different shale samples and the content of S1 in the synchrotron radiation X-ray scattering, it is determined that the lower limit of movable pore throat in the Cangdong depression is 20nm, and 50% to 70% of the measured pores are effective movable pore space, and the pore size is less than 1um. The lower limit of movable pore throat in Cangdong Depression is 20 nm, and 50%-70% of the measured pores are effective movable oil pores.