The 10th ECF Tech Award-Scientific and Technological Progress Award - Silver Award

Project: Research and Practice on Efficient Energy Replenishment and Pressure Restoration Technology for Low

Company:Oil and Gas Technology Research Institute

Project Title: Research and Practice on Efficient Energy Replenishment and Pressure Restoration Technology for Low-Yield Horizontal Wells in Changqing Shale Oil

Participating Enterprise: Oil and Gas Technology Research Institute, PetroChina Changqing Oilfield Company

Award Received: Scientific and Technological Progress Award - Silver Award

Achievement Level: International Advanced Level

Project Number: ECF-2025-SET-1013

Main Participants: Lu Hongjun, Yan Changhao, Mu Lijun, Bai Xiaohu, Bai Jianwen, Wang Pan, Ren Yong, Kang Bo, Ren Jiawei, Bai Yuen, Zhang Yushuo, Li Zhuanhong

Expert Review Comments:

International advanced level. This project targets the challenges of low productivity and rapid energy depletion in shale oil horizontal wells after initial production. It innovatively proposes the concept of “energy-replenishing re-fracturing”, forming a “fracture network–energy–medium” synergistic enhanced recovery system. Key technologies include old-fracture diagnosis before re-fracturing, precise energy replenishment, multi-stage temporary plugging to promote complex fracture formation, and integrated geological-engineering design. These advancements significantly enhance fracture complexity and reservoir stimulation volume, leading to substantial increases in recovery efficiency from old wells. The technology has been applied in more than 130 wells in Changqing Oilfield, resulting in over 1.5 million tons of incremental oil production. It demonstrates outstanding economic and social benefits and provides a replicable and scalable technological model for efficient development of mature unconventional oilfields.

Main Innovations:

Addressing the issue of declining productivity in mature tight/shale oilfields in Changqing, where conventional re-fracturing measures yield poor results, the project introduces a new energy-replenishing re-fracturing concept to enhance oil recovery. Key innovations include:

Conducting old-fracture diagnosis and targeted energy replenishment before re-fracturing to restore reservoir pressure;

Implementing integrated geological-engineering design to increase fracture density and improve sweet spot utilization;

Applying multi-stage temporary plugging and staged re-fracturing techniques to create complex fracture networks;

Achieving a synergistic effect among fracture expansion, energy replenishment, and medium displacement mechanisms.

These combined mechanisms optimize the flow channels, strengthen formation energy, and enhance imbibition and oil displacement, effectively boosting recovery rates in low-production horizontal wells.

Main Uses and Technical Principles:

In Changqing’s tight/shale oil mature regions, initial well stimulation is typically insufficient, and prolonged depletion production leads to low formation pressure and poor results from conventional re-fracturing. To address these challenges, the energy-replenishing re-fracturing technology was developed to improve flow channels, increase formation energy, and enhance both imbibition and displacement processes—ultimately maximizing recovery in old wells.

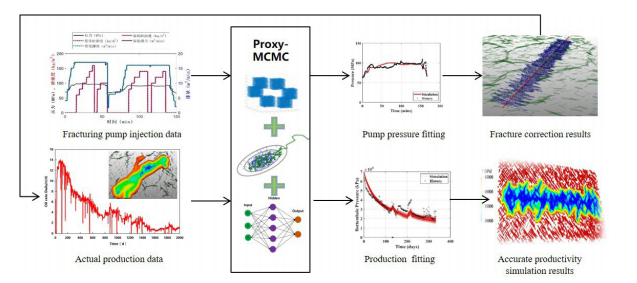

The technology workflow includes:

Old-fracture diagnosis and formation energy evaluation to identify re-fracturing targets;

Precise energy replenishment of depleted zones prior to re-fracturing;

Integrated geological-engineering design for high-density fracture placement to maximize sweet spot utilization;

Multi-stage temporary plugging and staged re-fracturing to construct a more complex fracture network;

Synergistic enhancement through the coordination of fracture expansion, energy replenishment, and displacement media.

This integrated approach enables the comprehensive restoration of reservoir flow capability and the significant improvement of oil recovery in mature shale reservoirs.

Technical Applications:

Field testing, pilot trials, and continuous applications have been conducted in Changqing Oilfield. After implementation, the average daily oil production of test wells increased from 0.83 tons to 13.39 tons, more than 15 times higher than the initial production, and the average recovery factor improved by over 8.9%.

As of September 2025, the technology has been successfully applied in more than 130 wells, resulting in a cumulative oil increment of over 1.9 million tons and generating nearly 1 billion RMB in economic value. It played a key role in helping Changqing Oilfield achieve a daily shale oil output exceeding 10,000 tons, providing an effective technical pathway for enhancing recovery in mature tight/shale oil zones.

The technology’s success in Changqing demonstrates its scalability and adaptability to other mature tight and shale oilfields in China, such as those in Southwest Oilfield, Daqing Oilfield, Xinjiang, and Qinghai. Furthermore, it holds international significance, offering valuable insights for low-recovery shale oilfields with strong heterogeneity worldwide. Through technology export and global collaboration, it strengthens China’s influence in the field of unconventional oil and gas development.