Project Title: Key Technological Breakthroughs in Ultra-Deep Complex Well Logging and Industrialization of Equipment

Participating Enterprises:

Hangzhou Fenghe Petroleum Technology Co., Ltd.;

Hangzhou Fenghe Measurement & Control Technology Co., Ltd.

Award Received: Scientific and Technological Progress Award - Gold Award

Achievement Level: International Advanced Level

Project Number: ECF-2025-SET-1003

Main Participants: Xu Tao, Zhou Jianwen, Xu Lin, Zhou Fuchang, Qiu Haitao, Wang Shenghuan, Li Fang, Liu Jie, Shen Xiongwei

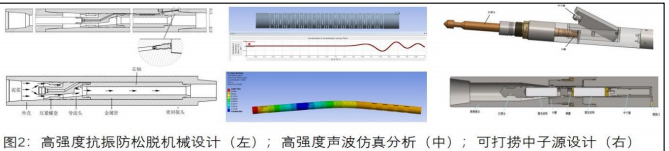

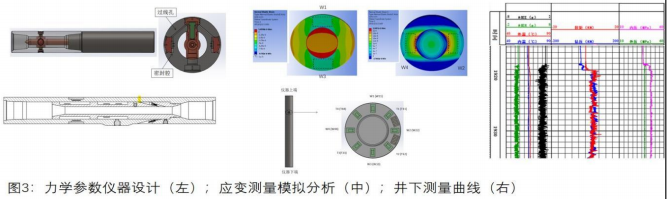

Expert Review Comments: International advanced level.This project addresses critical bottlenecks in logging for ultra-deep complex wells, achieving systematic breakthroughs in logging equipment design, signal acquisition, and real-time monitoring technologies under high-temperature and high-pressure conditions. It has developed a series of logging tools and processes capable of withstanding temperatures up to 230°C, pressures up to 206 MPa, and tensile forces up to 20 tons. Innovative achievements include high-strength acoustic isolators, integrated probes, non-contact ultrasonic borehole diameter measurement systems, and direct-push storage logging technology, collectively achieving a leap from “following” to “leading” in the field. Project outcomes were successfully applied in ultra-deep wells like the “Deep Earth Takuo-1 Well,” setting the world's deepest logging record. This significantly enhanced China's logging capabilities in ultra-deep, ultra-high-temperature/pressure, and high-inclination wells, establishing an independent and controllable industrial chain system. The equipment demonstrates high reliability with substantial economic and social benefits, providing crucial support for China's deep-earth and deep-sea oil and gas exploration and development strategy while offering broad international market prospects.

Main Innovations:

Invented a high-strength acoustic isolator for sonic logging tools, enhancing tensile/compressive strength to 20 tons—solving the bottleneck of inability to descend in complex wells.

Developed real-time geosteering monitoring, resolving blind measurement safety risks of memory instruments.

Developed the acoustic far-detection technology in boreholes, achieving a detection radius of 70 meters around the wellbore and solving the problem of "short detection range.

Main Uses and Technical Principles

Main Applications: For on/offshore mineral exploration and geological evaluation, sensors (acoustic/electric/nuclear principles) acquire physical parameters of subsurface formations at varying depths. This generates continuous log curves/images to indirectly derive:Lithology, Porosity, Fluid properties, Permeability, Formation pressure & temperature.Providing scientific basis for resource assessment, development decisions, and engineering optimization.

Technical Principle: By measuring formation properties near boreholes (e.g., electrical,acoustic,nuclear, mechanical characteristics), rock parameters (lithology, porosity, permeability, fluid properties) are indirectly acquired. Diverse logging tools—designed around distinct physical principles—cover multidisciplinary convergence of physics, electronics, chemistry, and computer science.

Technical Applications:

1) Application and Promotion in Domestic Oilfields

The project's technology and equipment performance metrics surpass those of comparable instruments from the world's top three giants in the ultra-high-temperature, high-pressure, and high-intensity technology field. It has become a powerful tool for detecting oil and gas reservoirs in deep-to-ultra-deep complex well conditions. It has been widely applied in China's Tarim, Southwest, Changqing, Daqing, Shengli, and Bohai oilfields. It has successfully completed hundreds of well runs in ultra-deep complex wells exceeding 6,000 meters and executed 10 well runs in national key projects at depths over 9,000 meters. Notably, it achieved the detection mission for China's first scientific exploration well targeting 10,000 meters—“Shen Di Ta Ke 1 Well”—driving a groundbreaking international technological advancement in China's ultra-deep oil and gas exploration.

2) Overseas Application and Promotion

The project equipment has accompanied CNPC Logging International to international markets, achieving extensive application in deep, complex oilfields across Iraq's Misan Oilfield, Chad, Nigeria, Turkmenistan, Kazakhstan, and other countries. This marks the successful global deployment of domestically produced high-end logging equipment, providing robust support for oil and gas exploration in Belt and Road countries.