The 10th ECF Tech Award-Scientific and Technological Progress Award - Gold Award

Project:Key Tech for Economical Development of Deep Coalbed Methane and Their Large-Scale Application

Company:Petrochina Coalbed Methane Company Limited

Project Title:Key Technologies for Economical Development of Deep Coalbed Methane and Their Large-Scale Application

Participating Enterprise: Petrochina Coalbed Methane Company Limited

Award Received: Scientific and Technological Progress Award - Gold Award

Achievement Level: International Advanced Level

Project Number: ECF-2025-SET-1007

Main Participants: Wang Chengwang, Wu Jianjun, Wang Yuan, Liu Chuanqing, Han Jinliang, Zhu Weiping, Zhen Huaibin, Yuan Pu, Chen Gaojie, Feng Yanqing, Ge Tengze, Wang Wei, He Pengbo, He Yanxiang, Liu Danlu

Expert Review Comments:

International Advanced Level.This project addresses the global challenge of developing coalbed methane deposits deeper than 2,000 meters. It systematically uncovers the patterns of deep coalbed methane accumulation and enrichment, innovatively establishes an integrated technology system combining comprehensive sweet spot evaluation with geological engineering development, and develops core processes including optimized high-speed drilling and completion, along with “black gold target volume dense fracture network fracturing.” These advancements significantly enhance single-well production and development efficiency. The project overcame bottlenecks such as extended horizontal drilling sections, challenging fracturing modifications, and low permeability in deep CBM. It achieved large-scale demonstration applications with daily production exceeding 10 million cubic meters and cumulative proven reserves surpassing 100 billion cubic meters. The achievements have been extended to multiple oilfields including Liaohé, Changqing, and Jidong, propelling China's deep coalbed methane industry from exploratory phases to large-scale development. This provides critical technological support for sustained unconventional natural gas reserve expansion and production growth, delivering significant economic and social benefits with broad application prospects.

Main Innovations

1.First to reveal the enrichment and accumulation theory of deep CBM, establishing anaccumulation model that supported a major strategic break through in China's deep CBM exploration.

2.Pioneered integrated geological evaluation and development design technologies.enabling the construction of China's first million-ton oil-equivalent deep CBM field.

3.Developed optimized and efficient drilling & completion technologies for deep CBM,filling the technical gap for fast and high-quality drilling in deep, complex coal seams.

4.Invented the "Black Gold Target" dense fracture network stimulation technology,advancing deep CBM as a new strategic replacement for natural gas in China.

Main Uses and Technical Principles

1.Developed a Replicable & Scalable Series of Technologies for Efficient Deep CBM Development

Based on the integrated approach of "Innovation-Application-Efficiency," thesetechnologies have facilitated the transformation of deep CBM from resources toreserves and from reserves to production.They have driven a revolutionary advancement in China's CBM industry, establishing deep CBM as a new strategic alternative and growth area for natural gas supply.

2.Ensured National Energy Security: By the end of 2024, the Daji Deep CBM Fieldhad cumulatively produced 985 million cubic meters of gas.This has secured stablegas supply for the Daning-jixian region and surrounding areas, ensuring warm wintersfor residents.

3.Significantly Contributed to National Carbon Reduction & Energy Transition:Total deep CBM production increase: 104.818 billion cubic meters. Equivalent toSaving 1.3 million tons of standard coal, Reducing CO2 emissions by 2.12 million tons.Cutting SOz emissions by 97,900 tons, Lowering dust emissions by 798,000 tons.

Technical Applications

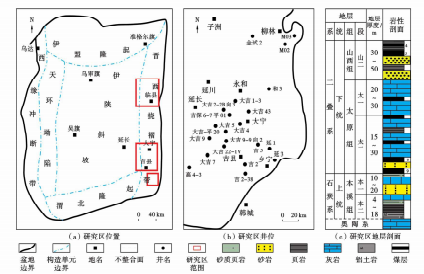

Theories and models of deep coalbed methane accumulation, quantitative reservoir characterization techniques, and dual-sweetspot quantitative evaluation technologies integrating geological and engineering data have enabled new breakthroughs in deep coalbed methane exploration and development within the Daning-Jixian block. Cumulatively submitted proven reserves of 112.162 billion cubic meters of deep coalbed methane, supporting China's first deep coalbed methane pilot project and the formulation and implementation of a 10x10⁸ m³/a development plan. This has driven a revolution in China's coalbed methane industry, positioning deep coalbed methane as a new strategic successor and growth area for natural gas. The findings have guided the implementation of appraisal wells in oilfields such as Liaohé, Changqing, and Jidong.

The ultra-large-scale precision fracturing technology has been successfully deployed across 180 coalbed methane, shale gas, and oil wells at the Coalbed Methane Corporation, Changqing Oilfield, Liaoning Oilfield, and Jidong Oilfield. Horizontal wells achieved breakthrough production rates exceeding 160,000 cubic meters per day, while vertical wells surpassed 67,000 cubic meters per day. Daily gas production now exceeds 10 million cubic meters.