The 10th ECF Tech Award-Technological Improvement Award

Project:Cleaning technology of drilling barrel in shale oil horizontal well

Company:Changqing Oilfield Shale Oil Development Branch;

Project Title: Cleaning technology of drilling barrel in shale oil horizontal well

Participating Enterprise: Changqing Oilfield Shale Oil Development Branch;

Award Received: Technological Improvement Award

Achievement Level: International Advanced Level

Project Number: ECF-2025-SET-1019

Main Participants: Zhang Yaohui, Ma Lijun, Huang Zhanwei, Ma Hongxing, Wang Xiaorui, Liu Weidong, Guo Chaoying, Gai Hong’en, Guo Sichen, Zhang Shuai

Expert Review Comments:

International advanced level.This project addresses the pain points of complex procedures, high costs, and lengthy cycles in horizontal wellbore cleaning operations for shale oil. It innovatively developed the “one-trip, seven-in-one” wellbore cleaning technology, integrating multiple functions including wellbore cleaning, sand flushing, scraping, brushing, fishing, well washing, and magnetic recovery. This enables a single run of tubing to accomplish multiple operational tasks. This technology features a compact structure, simple operation, and reusability, effectively enhancing operational efficiency while reducing construction costs and risks. The technology has been applied in 12 well operations at Changqing Oilfield, demonstrating significant economic and social benefits. It provides a practical new solution for the efficient, low-cost development of horizontal shale oil wells, holding considerable value for promotion and practical application.

Main Innovations:

The cleaning technology of shale oil horizontal well drilling tube in one trip breaks through the problem of conventional single treatment of wellbore and many times of tripping string. It integrates a variety of wellbore operation modes, and realizes the seven-in-one ' well opening, sand washing, scraping, brushing, fishing, well washing and magnetic absorption ' horizontal well operation mode of wellbore cleaning operation. It realizes the cleaning function of seven or more wellbores in shale oil horizontal wells in one trip, and adds a new engine for the current low-cost and efficient development of domestic shale oil.

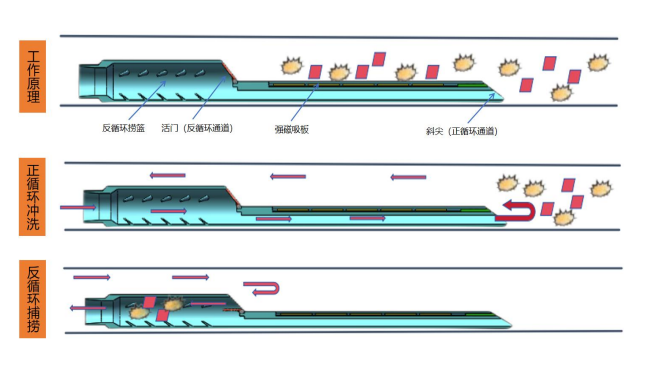

Main Uses and Technical Principles:

According to the characteristics of foreign bodies in the wellbore, the cleaning technology of one-trip drilling barrel for shale oil horizontal wells can be carried out by means of ' positive circulation and reverse circulation ' large displacement. The combination technology of ' horizontal well debris catcher + casing scraper + casing brush ' one-trip string is adopted, and the operation of ' conventional power + string ' is used to clean up the foreign bodies such as sand, wax, scale, rubber skin, cable head, metal debris and iron wire falling objects in the wellbore efficiently. Realize one trip drilling to complete seven or more wellbore cleaning functions, and meet the urgent needs of high efficiency and low cost of horizontal well wellbore cleaning.

Technical Applications:

The prospects for promoting the single-trip drilling clean technology for horizontal shale oil wells are promising, with its core advantages being prominent and field-validated: Since 2024, the technology has been applied in 12 well runs at Changqing Oilfield, achieving a single-trip drilling success rate exceeding 90%. Solid practical foundation: In terms of benefits, each well saves an average of 5-6 days in operation cycle, reduces production costs by ¥50,200, and generates additional crude oil production value of ¥109,600, resulting in a total well-level efficiency gain of ¥159,800. Significant economic returns: Cost control is achieved with a tool fabrication cost of only ¥28,500. Its simple operation and high reusability efficiency ultimately keep the average tool cost per well below ¥100,000. With low investment and high cost-effectiveness, it serves as a powerful tool for the large-scale, efficient development of shale oil, possessing the core conditions for widespread adoption in the shale oil development sector.