The 10th ECF Tech Award-Scientific and Technological Progress Award - Bronze Award

Project:Research on Key Technologies for Shale Gas Exploration and Development in the Complex Tectonic Belt

Company:Yangtze University

Project Title:Research on Key Technologies for Shale Gas Exploration and Development in the Complex Tectonic Belt of South China

Participating Enterprise: Yangtze University

Award Received: Scientific and Technological Progress Award - Bronze Award

Achievement Level: International Advanced Level

Project Number: ECF-2025-SET-1001

Main Participants: Zhu Guangyou, Chen Can, Sheng Guanglong, Wang Lei, Jin Jinen, Xiao Qilin, Tang Jun, Meng Jianghui, Lu Zhiyuan

Expert Review Comments:

International advanced level. This project focuses on geological and engineering challenges in deep shale gas exploration and development within the complex tectonic zones of southern China. It systematically carried out full-process research—from occurrence mechanism analysis, sweet spot evaluation, and compressibility classification to fracturing parameter optimization—forming an integrated technology system combining structural geology, reservoir geology, and engineering.

The achievements have been successfully applied in shale gas fields such as Changning–Weiyuan and Jianghan, significantly enhancing production capacity and development efficiency, with notable economic and social benefits. The project demonstrates important value for shale gas exploration and development in complex structural zones, particularly in innovations related to geological mechanisms, fracturing simulation optimization, and tracer technologies.

Main Innovations:

The project has achieved breakthroughs in three key areas addressing geological and engineering challenges in deep shale gas development in Hubei through integrated geology-engineering practices:

① Revealing the gas occurrence patterns and controlling mechanisms in new shale formations spanning the Precambrian to Cambrian periods.

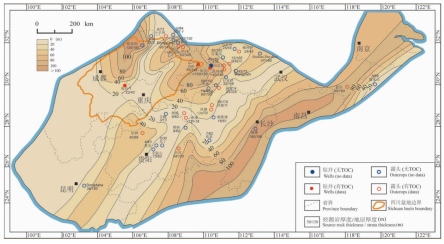

②Establishing a quantitative porosity model for deep shale reservoirs integrating TOC and chemical kinetics, while innovatively applying azimuthal AVO gradient difference technology to precisely characterize fracture anisotropy.

③Pioneering fracability classification criteria based on brittleness index, stress differential, and fracture development level.

④developing a full-cycle simulation and AI-powered fracturing parameter optimization system.

⑤Introducing trace chemical tracers for quantitative monitoring of gas/water production at individual fracturing stages.

Main Uses and Technical Principles:

Multiproxy geochemical reconstruction of paleo-cold seep events and deciphering organic matter enrichment mechanisms. Integrating Total Organic Carbon with chemical kinetics establishes a quantitative porosity model for deep shale reservoirs. Azimuthal AVO gradient differences are applied to characterize fracture anisotropy, enabling refined 3D reservoir evaluation. Multi-parameter fracability classification criteria (brittleness index, stress differential, fracture development) are developed. Full-cycle numerical simulation and AI algorithms optimize fracturing parameter design. Trace chemical tracers dynamically monitor gas/water production per fracturing stage to guide precision development. Collectively, these technologies systematically address critical challenges in complex structural zones—including Sweet Spot identification difficulties, inadequate fracturing results, and suboptimal development efficiency—thereby revolutionizing deep shale gas exploration and commercial development.

Technical Applications:

During 2023-2024, the Shale Gas Exploration Project Department of PetroChina Chuanking Drilling and Yangtze University collaborated on key technologies related to shale gas fracturing and dynamic monitoring in complex structural areas. They conducted multiple research projects and formulated fracturing enhancement measures and well placement plans for the Changning-Weiyuan shale gas field. Field implementation demonstrated >90% accuracy in fracture construction curve fitting and >90% accuracy in production dynamic data fitting. By comparing tracer data, the developed inter-well pressure migration identification method achieved over 90% accuracy in identifying flow pathways between fracture reference wells. The project implementation successfully increased reservoir utilization. The research and application saved significant time, labor, and management costs for the oil and gas field, providing a new solution for deepening the exploitation of shale gas reservoirs.