Project Title:Tartan All Purpose Pressure System

Participating Enterprise: Shanghai Tartan Energy Technology Co., Ltd.

Award Received:Scientific and Technological Progress Award - Bronze Award

Achievement Level: International Advanced Level

Project Number: ECF-2025-SET-1020

Main Participants: Yu Shaoyong, Yang Lin, Liang Zhenbo, Wang Guohui, Yang Kun

Expert Review Comments:

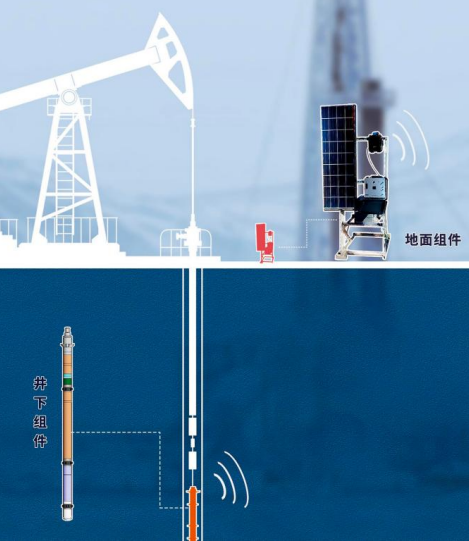

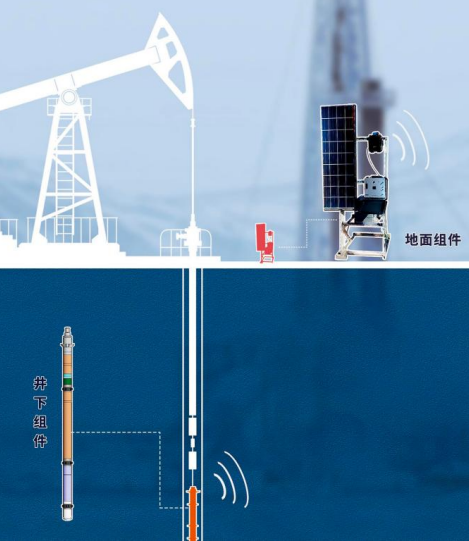

International advanced level. This project addresses the need for real-time monitoring of downhole temperature and pressure during unconventional oil and gas production. It innovatively developed a direct-reading intelligent wireless downhole pressure monitoring system based on “through-casing ultra-low-frequency EM + coherent reception + cloud-based analysis.” The system overcomes technical bottlenecks in reliable signal transmission under strong interference and deep-well weak-signal conditions, enabling continuous online monitoring and remote intelligent analysis of bottomhole temperature and pressure data.

The system features ±0.25%FS measurement accuracy, over two years of battery life, and strong anti-interference capability. It supports well testing without shutdown, pump-control linkage, and dynamic reservoir analysis, significantly improving production safety and operational efficiency. The system has been successfully applied in Canada, Daqing, and Liaohe oilfields, yielding remarkable economic and social benefits. It marks a domestically developed, independent breakthrough in wireless downhole monitoring technology with international competitiveness.

Main Innovations:

The project pioneered an end-to-end communication chain combining “through-casing ultra-low-frequency EM + coherent reception + cloud-based analysis,” solving the challenge of deep-well weak-signal decoding in strong interference environments.

The downhole tool (48 mm × 5.5 m) achieves ±0.25%FS accuracy and >2 years of battery life under conditions of 125°C and 20,000 PSI.

By integrating HDB3/BPSK modulation, Kalman filtering, and RS forward error correction with multi-station collaborative reception, the system significantly enhances decoding success rates.

Through platform integration with SCADA, DQA scoring, and closed-loop alarm management, it supports well testing without shutdown and enables linkage with pump-control systems.

Main Uses and Technical Principles:

Uses: Continuous online monitoring of bottomhole pressure and temperature during production, supporting optimization of production regimes, dynamic fluid management, equipment protection, well testing without shutdown, and dynamic reservoir analysis.

Principles: The downhole unit measures temperature and pressure data, encodes them into ultra-low-frequency EM signals, and transmits them upward through the “casing–formation–ground electrode/wellhead antenna” loop.

The surface receiver filters, amplifies, decodes, and integrates the signals into IoT/SCADA platforms.

Key technologies include electric dipole antennas, HDB3 Manchester + BPSK modulation, coherent accumulation, and forward error correction, enhancing anti-interference capability and communication reliability.

Technical Applications:

The system has been deployed in multiple wells in the Rolling Hills block of Alberta, Canada, achieving a reception success rate above 90%. In China, it was successfully applied in the Yi 10-20-44 and Liaohe Qingyang coalbed methane wells, achieving 100% reception success with 4-hour reporting intervals. The latter, at a depth of 2,351 m, set a global onshore record for the deepest production well with wireless bottomhole pressure monitoring.

Promotion Strategy:

Model sites are selected in stations with good grounding and controllable noise conditions. The standardized process (“well selection – baseline survey – joint commissioning – acceptance – review”) is replicated to accumulate regional parameter templates (carrier frequency / code rate / FEC / reporting cycle / alarm threshold).

The system is integrated with pump-control inverters and injection-production balancing systems for linked operations.

A “monthly DQA inspection + KPI review” mechanism is introduced, driven by dual indicators of “data quality and production benefits,” to continuously improve signal reception success and economic output.

To meet different oil company standards, the system supports multi-protocol integration and HSE workflow adaptation, enabling cross-contractor and cross-site collaboration.

Future work includes expanding the template library for “frequency band – code rate – FEC – reporting cycle,” validating system performance in higher-temperature, deeper, and more complex field environments for international markets, and establishing a training and certification system to help users achieve independent operation and maintenance capability.