The 10th ECF Tech Award-Technological Invention Award - Bronze Award

Project:Self reducing high strength self suspending proppant

Company:Beijing Kunlun Longyuan Petroleum Extraction Technology Co., Ltd

Project Title:Self reducing high strength self suspending proppant

Participating Enterprise: Beijing Kunlun Longyuan Petroleum Extraction Technology Co., Ltd

Award Received:Technological Invention Award - Bronze Award

Achievement Level: International Advanced Level

Project Number: ECF-2025-SET-1012

Main Participants: Ren Longqiang, Wang Guang, Wang Jianbing, Wang Lingyao

Expert Review Comments:

International advanced level. This project addresses key challenges in unconventional oil and gas fracturing operations, including the fragility of proppants, difficulty in sand transport, and high fracturing friction. It innovatively developed a self-drag-reducing, high-strength, self-suspending proppant that organically couples proppant and drag-reducing agent functions. The product features self-suspension, high strength, and low formation damage, effectively enhancing long-distance proppant transport and comprehensive fracture support capability.

In slickwater fracturing operations, the product demonstrates excellent suspension and compressive performance, significantly improving fracturing effectiveness and reducing reservoir damage. Initial field applications have achieved positive results. The project shows strong innovation and practicality, providing a novel material solution for deep shale gas and high-stress reservoir stimulation, with high industrialization and promotion potential.

Main Innovations:

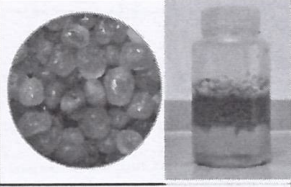

Self reducing high strength self suspending proppant is a novel fracturing proppant, distinguished by itsability to naturally suspend in clean water without the need for any thickeners or high molecular weightwater-absorbing materials. It has achieved significant technological innovations in self-suspendingtechnology, high-strength design, unobstructed entry into micro-factures, clean water sand-carryingtechnology, as well as reducing sand plugging risks and construction costs. It effectively addresses thechallenges of long-distance, high sand ratio sand-carrying in low-viscosity fluid systems, The suspensionof proppant in a clean water sand-carrying system not only simplifies the fracturing process, enhancingfracturing performance and single-well production in unconventional oil and gas fields. reduces waterusage, making it suitable for low-water fracturing, lowers costs, but also reduces environmental pollution.It holds promising application prospects and is worth promoting.

Main Uses and Technical Principles:

The product possesses unique self-suspending characteristics, high-strength support, environmentalperformance, and enhanced oil and gas production capabilities. Its main applications include complexfracture network volume fracturing in horizontal wells, supercritical carbon dioxide fracturing, cleanwater fracturing systems, and complex formation conditions. Through the "gas-philic" modification of theproppant surface, when it comes into contact with air during the mixing process, the gas will activelyencapsulate the sand particles. Microbubbles adhere to each proppant particle, reducing the relativedensity of the proppant particles. This effectively solves the problem of long-distance, high sand ratiosand carrying difficulty in low-viscosity fluid systems, achieving suspension of proppant in clean watersand carrying systems, and enhancing the fracturing effect and single well production ofunconventionaloil and gas fields. Its application not only simplifies the fracturing process, reduces water consumption, issuitable for low-water fracturing, lowers costs, but also reduces environmental pollution, providing amore efficient and environmentally friendly solution for oil and gas field development.

Technical Applications:

The 40/70 mesh, 52MPa gas-suspended proppant developed and produced by Beijing Kunlun Longyuan Petroleum Extraction Technology Co., Ltd. was first applied in the Da'an shale gas block of Zhejiang Oilfield in October 2023. The sand-carrying fluid used in this operation was formulated from return fluid and drag reducers, with alternating additions of conventional quartz sand proppant and gas-suspended proppant. As of April 18, cumulative gas production reached approximately 4.2 million cubic meters, with daily output exceeding 100,000 cubic meters—significantly higher than adjacent comparison wells. On November 28, 2024, our company's self-suspended proppant was deployed in the Dagang region by the Downhole Technical Services Branch of CNPC Bohai Drilling Engineering Co., Ltd. As of December 27, 2024, field acceptance confirmed that particle size, sphericity, acid solubility, and other metrics met both standards and design requirements. The proppant demonstrated stable fracture resistance with a breakage rate below industry standard limits. Suspension performance tests showed uniform dispersion and prolonged suspension time in gas-liquid mixtures without significant sedimentation or stratification. Field application yielded excellent results: smooth deployment during fracturing operations, high sand-carrying efficiency, high proppant integrity upon recovery, and sustained flow-through capability. The product's stable performance meets construction requirements and is suitable for deployment in similar reservoirs.