The 9th ECF Tech Award for Exploration & Production Technology

Project:PFOIM Technology for Oil & Gas Reservoir Casing and Mining Applications

Company:PetroChina Zhejiang Oilfield Company, Optical Science and Technology (Chengdu) Ltd , etc

Project Full Name:Permanent Fiber Optic Intelligent Monitoring Technology for Oil and Gas Reservoir Casing and its Application in Mines

Company:

PetroChina Zhejiang Oilfield Company

Optical Science and Technology (Chengdu) Ltd.

Institute of Geology and Geophysics, Chinese Academy of Sciences

The 715th Research Institute of China State Shipbuilding Corporation Limited (CSSC)

Awarded:Exploration & Production Technology

Standard: International Advanced Level

Projec Number: ECF-2024-SEP-1009

Principal Accomplishers: Liang Xing, Yu Gang, Wang Yibo, Li Dongming, An Shujie, Mei Jue, Yu Baoshi, Luo Yufeng, Fan Xiaodong

Key Innovation Points:

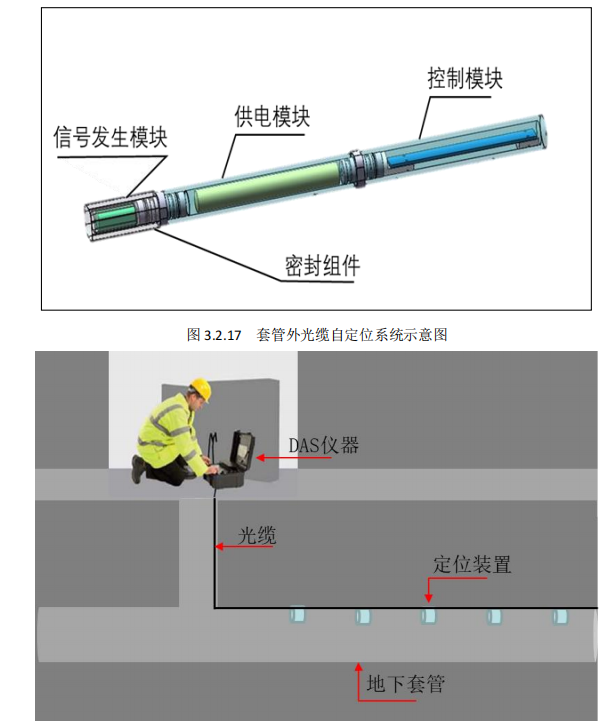

This project has innovatively developed intelligent optical fiber monitoring technology for shale oil and gas reservoirs underground. It has also developed a casing mounted permanent underground optical cable and its supporting series of tools, real-time monitoring and evaluation technology for casing mounted permanent optical fiber reservoir transformation, and intelligent monitoring and evaluation technology for oil and gas reservoir production dynamics based on fiber optic sensing big data, supporting the development of gas reservoir benefits.

Main Application and Technical Principal:

PetroChina Zhejiang Oilfield Company Branch, together with five units, relies on the scientific research project of PetroChina to address technical challenges such as incomplete installation and positioning technology of permanent optical cables outside the downhole casing, difficulty in accurately monitoring and evaluating reservoir transformation, difficulty in accurately monitoring "formation strain, temperature field, and three component micro vibration positioning" of oil and gas reservoirs, and lack of real-time monitoring technology for oil and gas reservoir production dynamics. The performance of fiber optic instruments continues to improve and is comparable to the international leading level. The overall application technology sequence is synchronized with the international level, becoming one of the few technologies that "runs parallel" with the international market. It has broken through the bottleneck technology "of fiber optic application in the oil and gas field, and has developed key technologies for intelligent dynamic monitoring of downhole fiber optic in oil and gas reservoirs through research and development, supporting the effective development of oil and gas reservoirs.

Technology Application:

The downhole fiber optic intelligent monitoring tangible technology formed by the innovation has significant replicable and promotable application value. By promoting the results of this project, it can not only help the group company to understand the production dynamics in real time in unconventional oil and gas field with lower labor cost, but also be more economical, safer, more environmentally friendly, and more effective, to realize and maintain the optimal production of oil and gas fields, and to promote the oil and gas reservoir to enhance the recovery rate by more than 10%. After the fiber optic monitoring technology is matured and applied in scale for fracturing and production dynamic monitoring, the comprehensive cost can be reduced to 1 million yuan/port, while the cost of conventional microseismic monitoring in wells in the past is 600,000-700,000 yuan/port, and 1.4-1.5 million yuan/times for multi-parameter production logging of wells with fluid production profiles (due to the high cost of production logging, not every well is usually tested with fluid production profiles), and the cost of fiber optic fluid production profiling of casing tubing is 2.0-2.5 million yuan/time. profiling in continuous tubing in casing is in the range of 2-2.5 million yuan/well.