The 8th ECF Tech Award for Exploration & Production Technology

Project:Tartan T-tracker Unconventional Oil & Gas High-temperature At-Bit Geosteering Tool

Company:Shanghai Tartan Energy Technology Co., LTD

Project Full Name:Tartan T-tracker Unconventional Oil & Gas High-temperature At-Bit Geosteering Tool

Company:Shanghai Tartan Energy Technology Co., LTD

Awarded:Exploration & Production Technology

Standeard: International Advanced Level

Projec Number:ECF-2023-SEP-1004

Principal Accomplishers: Lu Guoyi, Yang Xiaobin, Liang Zhenbo, Yang Lin, Liu Jiacheng, Li Hong, Wang Ping

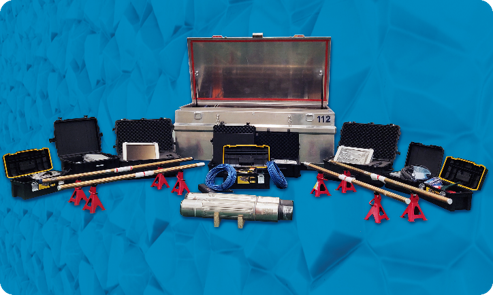

Tartan T-tracker Unconventional Oil & Gas High-temperature At-Bit Geosteering Tool

Key Innovation Points:

1. We have innovatively developed a downhole measurement tool that can withstand high temperatures of 175 ℃ while drilling. The circuit system was optimized using low-power design, thermal imaging detection, and other methods to enhance the high-temperature resistance of instruments in deep shale gas wells

2. Invented a three-dimensional gamma (Gr) imaging method. By using MWD real-time trajectory parameters and azimuth Gr data, interpolation algorithms have been used to solve the technical problem of not being able to visually display the imaging situation of wellbore trajectory and Gr value around the wellbore in existing technologies. In addition, it is recommended to customize the industry's top azimuth gamma sensor, which achieves a detection sensitivity of 0.52CPS/API through the analysis and calculation of multiple parameters

3. Integrated and innovative downhole measurement tools with short axial dimensions and zero measurement point length of 0.3m. Improved measurement accuracy and reliability, reduced the length of the short joint from 1200mm to 889mm, and reduced the distance between the measuring point and the drill bit from 0.5m to 0.3m

Main Application and Technical Principal:

1. The transmitter collects data from azimuth gamma sensors, gravity accelerometers, fluxgate meters, temperature sensors, and other sensors, which are converted into A/D and sent to the MCU for processing. The processed data is encoded and sent to the receiver through EM electromagnetic short transmission. The receiver receives the carrier signal, decodes the data, and sends it to the MWD, which is sent to the ground system through mud positive pulses, After processing by the ground system, real-time underground engineering and geological data will be presented

2. The receiver can be connected to traditional MWD from different manufacturers, with good compatibility and adaptability. At the same time, the QBUS interface widely used in high-temperature MWD in the industry is used as the interface for connecting the receiver and MWD

3. The entire system and circuit adopt modular design

Technology Application:

1. Since the large-scale application of this product in January 2021, as of April 2023, it has served a total of 127 wells

2. The high vibration Anye block has served a total of 20 wells; Yangzihao, Luzhou and other high-temperature blocks have served a total of 15 wells; Accumulated 43 wells in other Sichuan Chongqing shale gas blocks; Accumulated 49 wells in other blocks, with a total of 31263 working hours and a total footage of over 100000 meters

3. In the past two years, the technical service revenue has exceeded 100 million yuan, and the new profit has increased by tens of millions of yuan, achieving significant economic and social benefits