The 7th ECF Tech Award for Environmental Protection, Energy Saving & Emission Reduction Technology

Project:Application of Recoverable Fracturing Fluid and Supporting Technology in Changqing Shale Oil & Gas

Company:CNPC Chuanqing Drilling Engineering Co., Ltd. Changqing Downhole Technology Company

Project Full Name:Application of Recoverable Fracturing Fluid and Supporting Technology in Changqing Shale Oil & Gas

Company:Gepetto Oil Technology Group Co, Ltd

Awarded:Environmental Protection, Energy Saving & Emission Reduction Technology

Standeard: Domestic Advanced Level

Projec Number:ECF-2022-SEP-1004

Principal Accomplishers: Zhang Mian, Wang Wenwu, Gao Yan, Yang Boli, Xu Yingxin, Shao Xiuli, Yao Lan, Wang Yajun, Lv Li

LGF-80 Fracturing Fluid

Key Innovation Points:

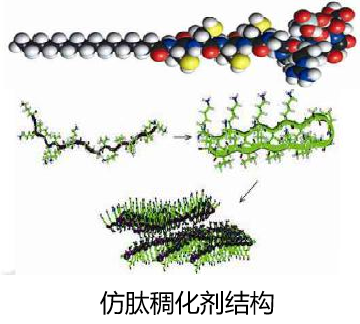

Developed a peptidomimetic ultra-long hydrophobic carbon chain thickener with sulfonic acid and phosphate temperature-resistant groups and methacrylic acid shear-resistant monomers, achieving a temperature resistance of 165 °C and a salt resistance of 100,000 mg/day for surfactant fracturing fluids. L; Through the guar gum fracturing fluid cross-linking agent with buffering low alkalinity and stepwise cross-linking function, high-hardness water such as produced water and fracturing acid compound drainage can be combined with guar gum sand-carrying fluid; Bacterial anti-corrosion, strong complex shielding and control and flooding technology realize the process of reusing the flowback fluid without removing ions, and the non-flowback part can be used for control and flooding; forming fracturing flowback fluid "electroflocculation-solid-liquid separation- PH value adjustment - sterilization" treatment process, optimized the operation parameters such as electrode spacing, current intensity, reaction time, etc. of electroflocculation treatment; independently designed and developed 3 sets of continuous electroflocculation series skid-mounted treatment with adjustable treatment capacity of 30-50m3/h The device realizes the industrial application of the process.

Main Application and Technical Principal:

Through cascade cross-linking, buffering low alkalinity and strong complexing technology, and molecular structure design of ultra-long hydrophobic carbon chain, the good performance of acid-pressed fluid drainage, produced water and other high-hardness water mixed with guar fracturing fluid is realized ; Improve the temperature resistance of clean fracturing fluids, and realize the mixed flowback fluid of guar gum, polymer and other types after fracturing, without the need to adjust water quality and remove ions, continuous online mixing construction and reuse of flowback fluids. Using electro-flocculation technology to integrate flocculation, air flotation, redox and other multiple functions, reveal the reaction mechanism of guar gum fracturing flowback fluid in shale oil, and optimize a set of processes such as electrode spacing, current intensity, and reaction time. parameters; self-designed continuous electroflocculation series skid-mounted treatment device with adjustable treatment capacity, realizing the industrial application of this process. The process steps are few, the secondary pollution is small, and the processing cost is reduced.