The 7th ECF Tech Award for Advanced Technology

Project:The Gyro Stable Drilling Tool

Company:Tianjin Jingbao Zhongtai Technology Co., Ltd

Project Full Name:The Gyro Stable Drilling Tool

Company:Tianjin Jingbao Zhongtai Technology Co., Ltd

Awarded:Advanced Technology

Standard: International Advanced Level

Projec Number:ECF-2022-SEP-1001

Principal Accomplishers: Jin Feng, Wen Lei, Lin Song, Sun Tieliang

The Gyro Stable Drilling Tool

Key Innovation Points:

The built-in gyroscope is driven by the turbine in the downhole drilling fluid environment with magnetic coupling transmission, and the core speed increasing components do not contact with the drilling fluid, and work completely in the gas phase.

The Gyro I built-in equivalent pair of balanced high-speed gyroscopes are sensitive to the acceleration of the drill bit and drill collar movement, which enables them to achieve synchronous response to the changes of drill collar and drill bit motion state, has a strong inhibition effect on various whirling vibrations of drill collar and drill bit, highlights the effect of drill collar pendulum torque, and assists in slope reduction. It is the first pure machine in China that can improve the quality of the well bore.

The Gyro II is equipped with a pair of eccentric high-speed gyroscopes, which can generate radial active high-frequency vibration and axial passive damping, and improve the aggressiveness and cutting stability of the drill.

The pressure drop consumed by the tool is less between 0.2-0.5Mpa; Leakage stoppage while drilling is allowed.

The maximum pressure resistance of the tool can reach 200MPa, and the temperature resistance can reach 270 ℃, which is suitable for tens of thousands of meters deep wells.

Main Application and Technical Principal:

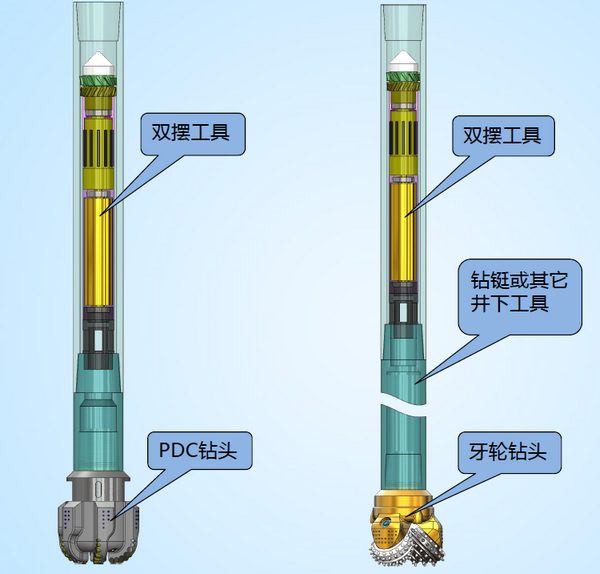

The Gyro Stable Drilling Tool I is mainly composed of turbine part, coupling part, stable gyro, etc. It is a speed increasing tool working in the gas phase. The tool is built with equivalent two pairs of balanced gyroscopes, which rotate at high speed under the drive of drilling fluid. In view of the whirl generated by the bit, the gyroscopes rotate at high speed to produce an integral effect, so as to achieve the convergence of various vibrations of the bit and drill collar. The inhibition effect of gyroscopes on the radial and axial acceleration is very obvious. The inhibition of the acceleration of the bit and drill collar can reduce the interactive vibration between the bit and the drilling string system, thus reducing the occurrence of whirl.

The Gyro Stable Drilling Tool II has a broad spectrum of applicability to the drill bit. By adjusting the eccentric gyro, it can generate radial active high-frequency vibration and axial stress vibration (equivalent axial vibration reduction). Combined with the resistance of the drill bit, it can greatly reduce the change rate of the resistance of the drill bit, reduce the working torque, strongly restrain the stick slip phenomenon of the drill head, improve the rock breaking efficiency of the drill bit, and extend the drill bit footage.

Technology Application:

Generally used in the field of drilling speed increasing. The Gyro Stable Drilling Tool I and II are mainly used in deep wells, high temperature and high pressure, and difficult rock formations.

High hardness stratum: such as Cambrian dolomite, with rock compressive strength of 200~250MPa

High plastic stratum: such as Jimusar Lucaogou Formation mudstone, with compressive strength of 150~270MPa

High temperature and high pressure wells: such as Tarim Kela Block, 158 ℃ underground

Very thick gravel layer: for example, in front of Tarim Mountain, 10MPa mudstone and 150MPa gravel alternate hard and soft.