ECF2021 Award for Digital & Intel Tech (China)

Project:Intelligent Oil Recovery Tech in Jimusar Shale Oil

Company:Jiqing Oilfield of Xinjiang Oilfield Company

Project Full Name:Intelligent Oil Recovery Technology Application in Jimusar Shale Oil Area

Company:Jiqing Oilfield Operation Area of Xinjiang Oilfield Company

Awarded:ECF 2021 Oil & Gas Tech Innovation Award of Digital & Intelligent Technology (China)

Standeard: Leading Level in China

Projec Number:ECF-2021-SET-1001

Principal Accomplishers: Ye Junhua, Liu Jianzhong, Chen Yu, Ma Jiangbo, Zhu Sijing, Jin Bo, Zhang Zhilong, Gao Liang, Zhou Yi

Key Innovation Points:

Adhering to the fundamental orientation of "simpler oil production, easier safety and smarte! environmental protection", the new intelligent oil production mode is realized through technological innovation and management innovation. Oil production is automated from bottom hole production to well station gathering and transmission, from bottom hole condition monitoring to surface equipment monitoring, and all parameter control and data acquisition are realized without manual on-site operation.

The oilfield development management mode of "unmanned well inspection and fault inspection" is established, and the man well ratio of oilfield management is reduced from 0.35 to 0.15; The production organization mode of "production joint command center has been constructed to realize the integration of early warning. analysis and linkage command, and the management efficiency has been improved by more than 60%. The "all-weather and three-dimensional" safety supervision and control mode has been established to realize the real-time monitoring of various operations and on-site videos in the oilfield, so as to improve the safety and environmental protection control; The application technology of smart networking" in oil field has been formed to realize "uniformity, completeness and accuracy of production parameters.

Main Application and Technical Principal:

Main Application :

simplify the process flow from oil production to gathering and transportation surface.

improve the intelligent level of production management.

Boost the transformation of production organization mode and reduce the amount of patrol inspection by 85%.

Improve labor efficiency and reduce the amount of sampling work of operation posts by 70%; The man well ratio of oilfield management decreased from 0.35 to 0.15.

Improve the ability of safety and environmental protection management and control。

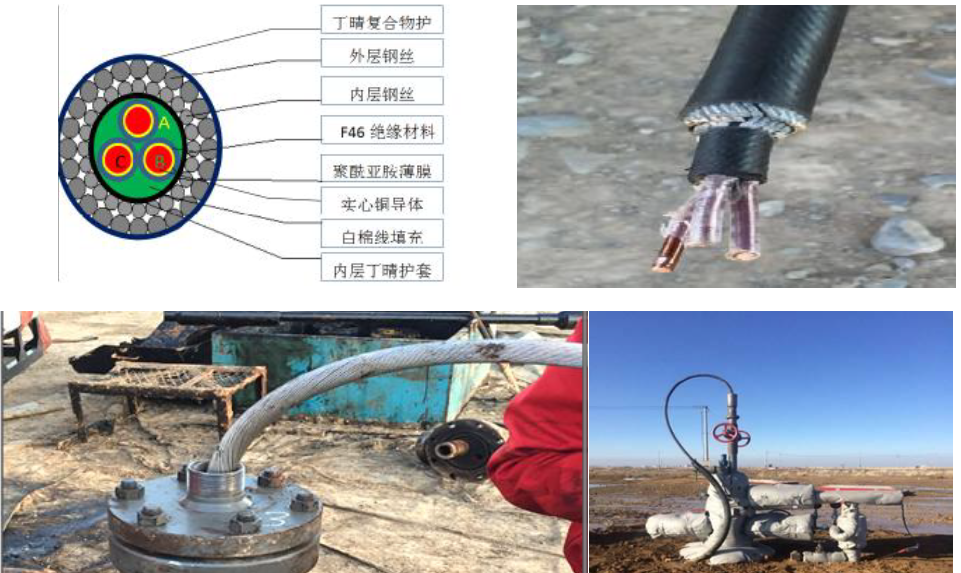

Technical principle:The rodless electric submersible screw pump oil production technology is used to replace the conventional mechanical oil production technology, which realizes the optimization and simplification of wellhead process, the reduction of patrol inspection and maintenance workload and the elimination of potential sources of wellhead safety and environmental protection: Single well on-line measurement + microwave water cut analysis are used instead of manual measurement and sampling, which realizes the accurate control of production data and the reduction of measurement workload of operators; Using data remote transmission + intelligent networking technology instead of conventional data acquisition and transmission technology, the successful transformation of oilfield lOT to digitization and automation has been realized; it ensures that the big data of oilfield development is "complete complete and accurate” and provides a guarantee for the intelligent analysis of production data in the background.