The 9th ECF Tech Award for Environmental Protection, Energy Saving & Emission Reduction Technology

Project:Unconventional Oil and Gas CO2 Fracturing Technology and Industrial Application

Company:CNPC Chuanqing Drilling EngineeringCo.Ltd.Changqing Downhole Technology Company

Project Full Name:Unconventional Oil and Gas CO2 Fracturing Technology and Industrial Application

Company:CNPC Chuanqing Drilling Engineering Co. Ltd. Changqing Downhole Technology Company

Awarded:Environmental Protection, Energy Saving & Emission Reduction Technology

Standard: International Advanced Level

Project Number:ECF-2024-SEP-1004

Principal Accomplishers: Xia Yulei, Wang Wenbin, Zhang Hongzhong,Lan Jianping, Li Zefeng, Ye Sai,Liao Ming,Yao Wei, Wang Yaru

Key Innovation Points:

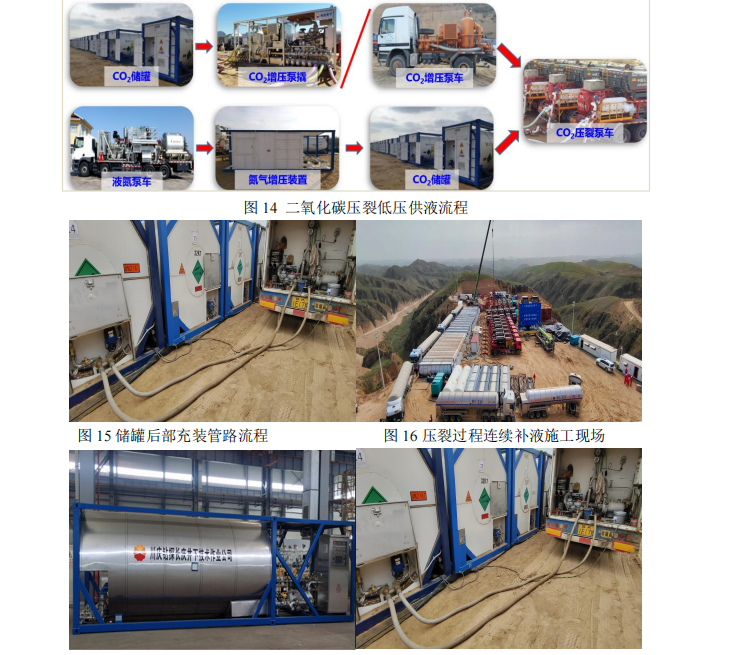

The mechanism of CO2-induced reduction of fracture pressure and complex fracture propagation in tight sandstone was comprehended, and the pH variation of the mixed system of formation water and CO2 in Changqing shale oil and gas was clarified. The optimal design of CO2 fracturing for shale oil and gas and the production technology after pressure were formulated, and the state transformation of CO2 in the surface-wellbore-formation process was determined. It has accomplished the comprehensive optimization of CO2 fracturing construction equipment and process flow, with the total power of CO2 equipment reaching 5000 HHP, the on-site liquid CO2 storage capacity amounting to 2000 tons, and the construction displacement exceeding 10 m3 /min of industrial operation capacity. The safe operation procedures and joint operation mode were established, and the overall technical strength is at the international leading level.

Main Application and Technical Principal:

Carbon dioxide fracturing is a novel reservoir transformation technology where liquid carbon dioxide partially or entirely substitutes water-based fracturing fluid to accomplish water-less and water-free fracturing. It possesses the merits of rapid flowback and low reservoir impairment, and is applicable to unconventional reservoirs with high water sensitivity and strong water lock. It constitutes an essential means for implementing the green and low-carbon development strategy in the domain of reservoir transformation. The average increment of CO2 fracturing was 52.7%, and the stable production duration was over 2 years, effectively alleviating the pressure of flowback fluid treatment and significantly reducing the consumption of water resources. From 2021 to 2023, the Changqing Underground Technology Operation Company of Chuanqing Drilling has accomplished 141 carbon dioxide fracturing operations, achieving a carbon emission reduction of 257,000 tons, equivalent to the planting of 2,270 trees, saving electricity by nearly 25,000 degrees, reducing wastewater treatment by approximately 223,000 square meters, and attaining liquid carbon dioxide storage of 172,000 square meters. The comprehensive economic benefit was 452.29 million yuan.

Technology Application:

From 2021 to 2023, a total of 141 carbon dioxide (CO2) enhanced fracturing (EF) operations have been completed, resulting in a carbon emission reduction of 257,000 tons. Aiming at shale oil in Changqing region

In view of the reservoir characteristics of extremely low matrix permeability and porosity, small seepage channels, low pressure coefficient and insufficient development energy in Changqing shale oil reservoir, the company adopted CO2 pre-fracturing technology, which utilized CO2 pre-fracturing to create a complex slit network, CO2 energy-enhancing and viscosity-reducing capacity of crude oil during well casing, and the replacement effect of CO2 dialysis during production to achieve capacity enhancement. Aiming at the problems of poor physical properties, strong non-homogeneity, slow energy transfer and low fluid drainage efficiency of the reservoir in Changqing shale gas reservoir, the company carried out CO2 pre-injection and CO2 accompanied injection energy-enhancing fracturing, which mainly utilized CO2 to increase the energy of the formation and fluid-carrying capacity of drainage, and realized high-efficiency post-pressure drainage, thus reducing the damage of the reservoir and increasing the production capacity of a single well, and the rate of one-time post-pressure jetting was 86.7%, which was 41.7% higher than that of the neighboring wells that were routinely fractured, and the average drainage rate of the wells was 86.8%. The average fluid discharge cycle was shortened by 7 days, and the average non-resistance flow rate of horizontal wells was 53.7×104 m3 /d, which was 45.9% higher than that of the neighboring wells, and CO2 foam fracturing was popularized and applied to a total of 33 wells in Changqing, Da Niu Di, and other gas fields in North China, and the average non-resistance flow rate increased by 4.9585×104m3 /d compared with that of the 69 comparison wells of hydraulic fracturing, and the average non-resistance flow rate of the 69 comparison wells was 4.9585×104m3 /d.

Compared with the average unimpeded flow rate of 4.9585×104m3 /d in 69 hydraulic fracturing comparison wells, the average unimpeded flow rate increased by 8.8728×104m3 /d, with an average increase of 178.9%. In total, 15 wells and 18 levels of carbon dioxide dry sand fracturing were completed, which was a record high.

In total, 15 wells and 18 levels of wells were completed, with the maximum working well depth of 3454m, the maximum single well sand volume of 45.2m3, the maximum sand ratio of 25%, and the maximum construction displacement of 6.0m3 /min.