The 8th ECF Tech Award for Stimulation & EOR Technology

Project:Anton Real-time Iterative Fracturing Technology

Company:Anton Petroleum Technology (Group) Co., LTD

Project Full Name:Anton Real-time Iterative Fracturing Technology

Company:Anton Petroleum Technology (Group) Co., LTD

Awarded:Stimulation & EOR Technology

Standard: Domestic Advanced Level

Projec Number:ECF-2023-SEP-1005

Principal Accomplishers:Wang Zhaozhou, Liu Yujian, Xie Lin, Hou Lin, Lin Xiaohai

Anton Real-time Iterative Fracturing Technology

Key Innovation Points:

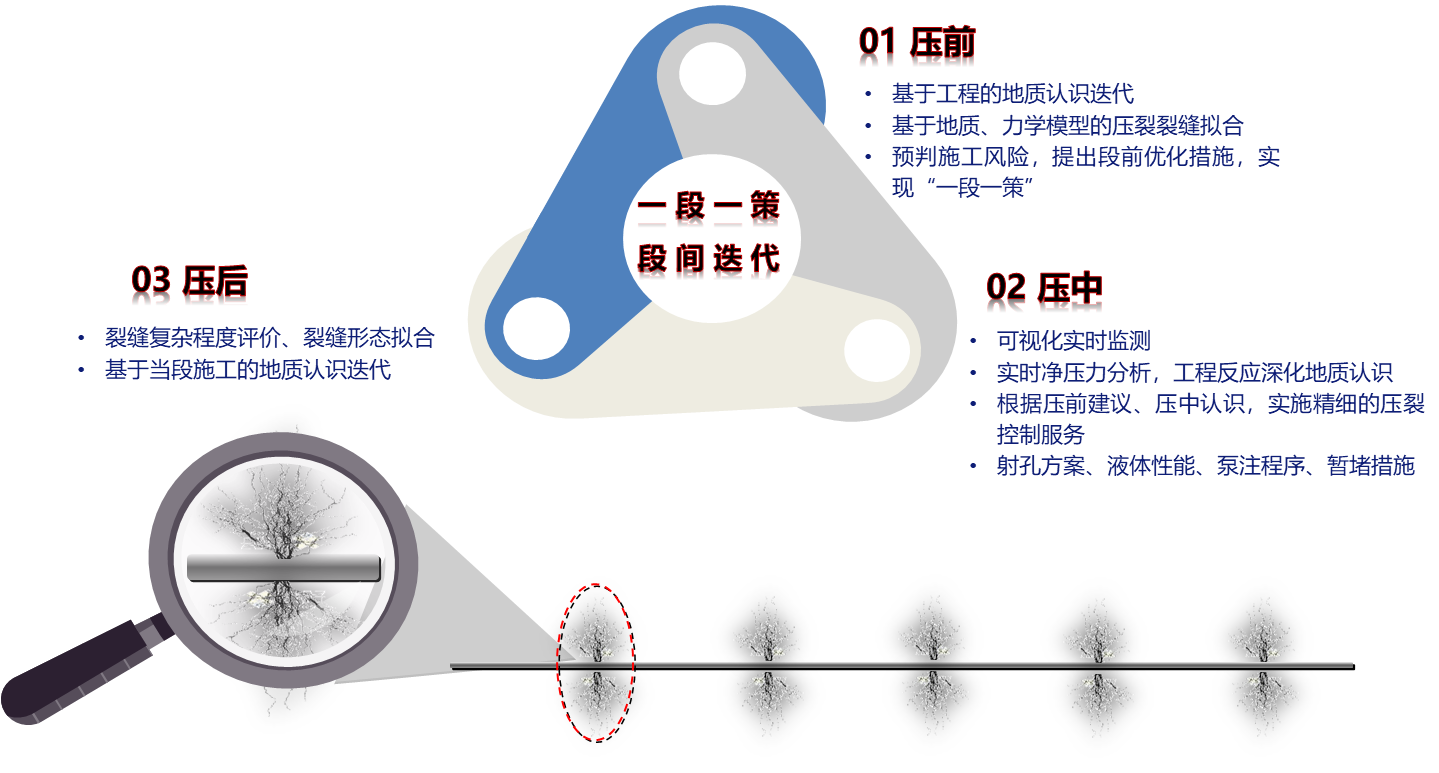

1. With the core of net pressure analysis in the fracturing construction section and iterative optimization technology for inter segment fracture simulation, real-time analysis of hydraulic fracture propagation morphology, geological understanding, and real-time iteration of engineering schemes are carried out to propose dynamic optimization schemes in the section and adjustment suggestions for inter segment schemes, achieving dynamic optimization of the fracturing scheme.

2. Taking into account reservoir heterogeneity, the impact of complex natural fractures on hydraulic fracture propagation, the migration of proppants in complex fracture networks, and the water hammer effect after pump shutdown, unconventional hydraulic fracture simulation techniques and fracture network complexity evaluation techniques have been developed that are closer to the true fracture morphology.

Main Application and Technical Principal:

Technical principle: Anton real-time iterative fracturing technology is an integrated application of geological engineering integration and intelligent fracturing technology. Through real-time net pressure analysis, hydraulic fracture simulation, and fracture network complexity evaluation technology during the fracturing construction process, the expansion form of hydraulic fractures is analyzed and judged in real time. The geological understanding and engineering scheme are iterated in real time, and dynamic optimization schemes are proposed in sections and adjustment suggestions are made between sections to achieve dynamic optimization of fracturing schemes.

Technical process:

1) Pre fracturing simulation and optimization: Establish a fracturing analysis model and risk prediction.

2) Real time analysis and optimization during fracturing: Real time monitoring of fracturing parameters throughout the entire process, analysis and judgment of hydraulic fracture extension mode, proposing dynamic optimization suggestions and complex warnings.

3) Post pressure analysis and summary: Qualitative and quantitative evaluation of single section hydraulic fracture morphology and parameters, iterative geological understanding based on fracture analysis results, and improvement of key construction points for the next section and next well.

Technology Application:

Improve the effectiveness of fracturing transformation through a precision fracturing control system that includes real-time analysis of fracturing, precise control of processes, and in-depth evaluation of effects

Optimization and evaluation mode for integrated fracturing implementation in geological engineering

Remote command, real-time adjustment, and big data optimization management mode

Currently, more than 100 wells and 2600 sections have been implemented on 33 platforms, with significant results

Risk control: achieve "zero loss section" and 100% integrity of the 170000 meter long wellbore after fracturing

Cost reduction and efficiency improvement: A shale gas area has reduced comprehensive costs by over 10 million yuan, and increased well average EUR by 8.3%

Deepening understanding: quantitative understanding of artificial fractures and deepening research on the main control factors of production capacity